Top 5 Packaging Trends of the Future

Recycling, upcycling, and making sustainable changes in production and the supply chain are part of preserving the environment. In line with ensuring that producers of goods genuinely play their role in this endeavour, there is the legally regulated Extended Producer Responsibility (EPR).

The basic premise of the EPR was to create a system where producers are fully responsible for their products—from design to recycling. It focuses mainly on the packaging of products, as this tends to be where the most significant issues are, especially the disposal of packaging. EPR compliance is important not only because it is legally obligatory, but also because it will show that you care about your products and your environment, and your processes prove this.

1. Recyclable Packaging

In a bid to reduce their carbon footprint, a lot of producers are going this route in their packaging process. Recyclable packaging is also a good alternative because most countries have banned single-use plastics as they are more damaging to the environment. This packaging can be recycled and reused, which also makes it a less expensive option for packaging products.

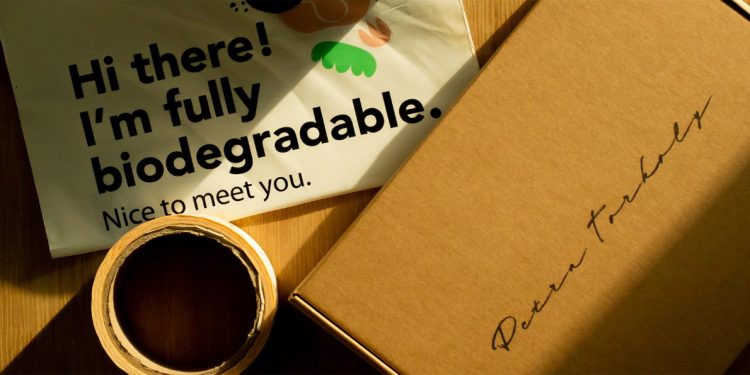

2. Biodegradable Packaging

This packaging is much less damaging to the environment than all others, provided it is disposed of correctly. Biodegradable packaging is made from items like starch or cellulose; some are plant-based, made from hemp, sugarcane, and coconut, along with others like renowned seaweed that will not harm the environment.

3. Edible Packaging

While this may sound a little far-fetched, edible packaging is made from material that is not harmful to the human body. A good example is packaging made from milk protein, used as casing film around food products. Other companies are even making edible cutlery to go along with edible packaging!

While this may sound a little far-fetched, edible packaging is made from material that is not harmful to the human body. A good example is packaging made from milk protein, used as casing film around food products. Other companies are even making edible cutlery to go along with edible packaging!

4. Nanotechnology

Nanotech can be employed at all levels in the supply chain process. It helps with anti-counterfeiting technology for the end product, and nanotech mixed with polymers enhances the tensile strength of packages. It also helps keep products safe from dirt, stains, and dust. Nanotech can also help detect any chemical changes in food and monitor its freshness.