Treasures of Roman Yorkshire

Although it was at its north-western fringe, Roman Britain was still able to access connections to the wider Roman Empire. International imports of olive oil, wine, and the traditional fish sauce garum are well known and there were also significant amounts of internal trade within the province. This was especially true for trade within different regions of Britain. In some cases, this trade is pragmatic; for example, the pale yellow-white stone visible in the Multangular Tower in York is the typical limestone used throughout Eboracum.

The Yorkshire fortress: the south-west corner tower of the fortress at Eboracum, which still

stands today. Known as the Multangular Tower, it is built from Magnesian Limestone bricks,

of a type that was brought into York from elsewhere in Yorkshire.

Geologically it is a ‘Magnesian Limestone’, but archaeologically it had been transported here from elsewhere in Yorkshire. The Roman settlement at modern-day Tadcaster was a probable major source; the Latin name of that town, Calcaria, is taken from its connection to the stone. The limestone was an easier material to work and carve into dressed stone blocks than the natural coarse-grained sandstone that is the bedrock of York itself. Elland Flag, from near Leeds, was also used in roofs at Shiptonthorpe. So local resources were exploited where it was practical and viable to do so. In this section I will introduce some of the ‘Yorkshire’ flavour of regional trade in Roman Britain.

Enamelled Brooches

Fashions changed quickly in Roman Yorkshire. A group of copper alloy brooches with enamelled decoration may have been produced in the region. So-called ‘headstud’ brooches were decorated with one or two circular studs at the apex of the bow. We know that Castleford was producing enamelled metalwork because more than twenty-five fragments of crucibles have been found here as well as hundreds of clay moulds for all of the metal products. These include some types of brooches, such as the headstud type.

The brooch in the image was found in Featherstone, just south of Castleford, and appears to be unfinished. Copper alloy is bright and brassy – the green on the surface is a product of its oxidation. When you look at it, think of the bright and garish colours these brooches originally contained. They were small, functional, but impactful accessories. It is plausible that it is one of the products of the local brooch production industry.

Bright copper alloy headstud brooches with colourful enamel decoration were a popular dress accessory in Roman Yorkshire and were made in the Castleford area. From Featherstone, near Castleford (PAS: SWYOR-92A6C9). (© West Yorkshire Archaeology Advisory Service, CC BY SA 4.0)

Lead Pigs

A group of large lead ingots, known as ‘pigs’, have been found around Brough. There are at least nine of them from this area. Each pig measures nearly 60 cm in length and weighs around 85 kg. Several are inscribed with the abbreviation ‘SOCIO LUT BR EX ARG’, which translates as: ‘The product of the Lutudarisensian partners: British lead from the lead silver works.’ The lead ore used to make these ingots could be a by-product of silver mining. It was found in the form of the mineral galena (lead sulphide), which occurs in the Carboniferous limestone regions of Britain – the Mendips (Somerset), Flintshire (North Wales), Shropshire, Derbyshire, and Yorkshire. The naming of the production place on some of the pigs located their origin to the site of Lutudarum in Derbyshire. The products of the Derbyshire mines were probably sailed down the River Trent to Brough before being transported by sea elsewhere in Britain or, more likely, to the Continent.

Ceramic Production

Ceramic tableware was much more commonly used than the metal plates and jars that made up the Knaresborough Hoard. With links to the empire, there are numerous types and forms of pottery imported into Roman Britain – olive oil amphorae from the Mediterranean, the commonly found glossy red Samian ware from Gaul, and dark brown beakers from the Rhineland bearing mottos in white paint, such as ‘Long life to you’ and ‘Drink [up]’.

Clay was cheap and easier to acquire and so it is not surprising to find a whole industry of potteries in the region. The different clays found throughout Yorkshire each had naturally different compositions. Roman potters could also add in sand, shell, or other hard materials as a ‘temper’ – to help prevent the pot from breaking when it was baked in the kiln. These differing properties, along with different traditions for making certain types or sizes of pot in different places, created a landscape of different pottery ‘wares’ throughout Roman Yorkshire. Some of the earliest ceramics were made by the army. The 9th Legion in York made floor and roof tiles to be used in the early fortress. Small units also made ceramics: the Cohors IIII Breucorum produced mortaria (wide grinding bowls for food preparation), roofing and hypocaust tiles in the pre-Hadrianic period at Grimescar, 5 km east of the fort at Slack. These stamped tiles are used at Slack, also at Castleshaw and Castleford, as well as Manchester, showing that not every fort needed to produce its own supply.

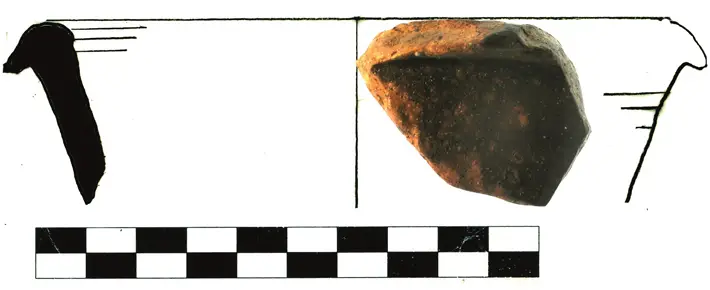

This pale yellow fabric with red-painted decoration is a typical product of the Crambeck kilns. It is a rim sherd of a mortarium, the deep bowls used for preparing sauces. In the Yorkshire Museum (YORYM: H5004). (© York Museums Trust, CC BY SA 4.0)

Cantley Kilns

Over forty kilns have been found in the area south and east of Doncaster, centred around Cantley and Rossington Bridge. They started producing local wares in the mid-second century. Different kilns may have been owned by different potters and were probably used at different times, but the density of kilns here shows that this was a landscape of potters. It can be quite variable, but the main sort of ceramic produced here is particularly hard and dark grey in colour. Many of the jars were burnished – polished smooth before they were fired in the kiln – and so took on the shiny, dark lustre of this process.

Potters making mortaria often stamped their names on the rim of the vessel. We know of Sarrius, Setibocius, and Secunda all making these vessels in Cantley in the period c. AD 135–170, and Virrinus who was working slightly later, c. AD 150–180. Sarrius may have also had close connections with, or even owned, other potteries in the Midlands at the Mancetter-Hartshill region. His mortaria have been found on the Antonine Wall, Corbridge, and Catterick but Doncaster and its hinterlands were the long-term main consumer of the pottery from Cantley and Rossington Bridge.

Dark jars and dishes were the typical products of the Cantley kilns. This rim fragment was found in Edlington, only a few miles from its production site (PAS: SWYOR-3F1141). (© West Yorkshire Archaeological Services, CC BY SA 4.0)

Crambeck Ware

The fourth-century pottery industry based around Crambeck, between York and Malton, produced some of the most astonishing pots in Roman Britain. The typical Crambeck vessel was made from a pale cream-coloured fabric and decorated with a thin red paint at its surface. It doesn’t seem to have been distributed too far beyond the north and east of the country, with its greatest popularity firmly within Yorkshire.

In most other places in Britain by this time the dead were buried in the ground (inhumation), but in Yorkshire a tradition of cremation continued at the same time. The Crambeck ware industry is noted for the creation of cremation jars with human faces – whether they depicted the individuals contained within them (like on a tombstone) or a patron deity we can only speculate. Other playful designs included stripes, dots, stars, and stick figures.

In most other places in Britain by this time the dead were buried in the ground (inhumation), but in Yorkshire a tradition of cremation continued at the same time. The Crambeck ware industry is noted for the creation of cremation jars with human faces – whether they depicted the individuals contained within them (like on a tombstone) or a patron deity we can only speculate. Other playful designs included stripes, dots, stars, and stick figures.

Top image: Excavation of a kiln at Crambeck by Philip Corder in 1926–27. The rounded shape of the kiln, in which a man is standing, can be made out in the lower right corner. In the archive of the Yorkshire Museum.

Article taken from ‘Treasures of the Roman Empire’ by Adam Parker, published by Amberley Publishing, £15.99 paperback