3D Printers – What to Expect?

Technology moves on whether we strive to catch up with it or not, and for a long while now, 3D printers have been a reality. We can print anything, from metal car parts to houses. This is a very powerful tool that can bring much good into the world. Take the lockdown, for instance. People are designing and printing expenders for medical masks, that allow people to wear them more comfortably, especially medical staff, who have to wear them all day long. Or special extensions for doorknobs, in order to open them with an elbow, instead of using the palm. The possibilities are endless, and if you are looking to buy 3D printer UK has lots of options to offer. But first, let’s get back to the device itself and see how it works.

How does a 3D printer function?

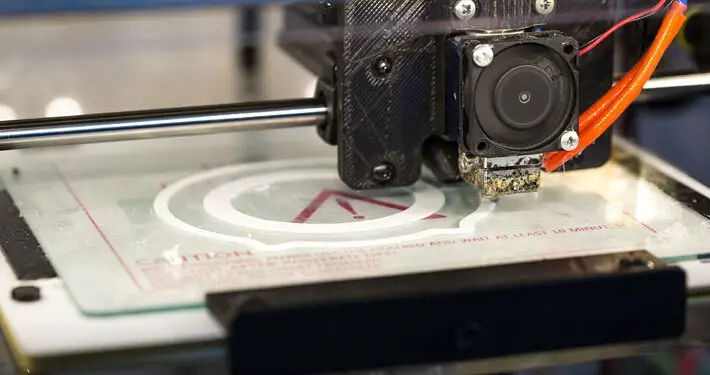

This brilliant device is capable of producing any sort of shape from different materials, the most popular being different polymers and plastics. All 3D printers use computer-aided design (CAD) for guidance and basically follow the pattern of whatever you designed on the computer. There are many print-ready files available for download nowadays, and if design isn’t your strong suit you can try and print some of the patterns available online. When you set up the device, you have to “feed” the material to the printer thorough a special port and the magic begins! The printer adds layers and layers of material until the intended shape is complete. This basic principle is called additive manufacturing (AM) and it gives the opportunity to create shapes with very high precision.

What to expect in the near future?

As we know, technology is moving on at an alarming pace and we have new devices and better versions of devices coming out every year. So what’s the forecast for the 3D printers in the near future?

There’s a definite rise in the number of manufacturers. So the market is becoming more and more competitive, which is a good sign, given that the result of this competition is a better product. This also means that material development is going to rise as well. Material is the only thing that can somewhat slow 3D printers down from spreading like wildfire. Models that are affordable to the general public, and that are not intended for large scale manufacturing, don’t have enough options yet when it comes to the polymers they use.

Design tools will grow and expand. Nowadays, the software is a weak point in the whole process, and it doesn’t allow a very fluid work system. So the software itself has to be more sophisticated in order to allow better simulation results.

More and more collaborations with different industries, research facilities and businesses

A lot of work has to be done in the field of in-process monitoring and control. Post-production monitoring is very time-consuming and the manufactured pieces might slightly vary from device to device and from piece to piece.

As you can see 3D printing is just starting to gain real momentum and will soon be ready to take over the manufacturing world. There are still problems keeping that from happening, but they are all solvable and temporary. 3D printing is something that will influence not only product manufacturing but also art and medicine. The results in the latter are particularly interesting. AM is a safe way to produce prosthetics and medical gear, and there is extensive research being done in the field of bioprinting.

So never stop educating yourself to the news on the tech front and it will definitely pay off. If bioprinting of organs can become a reality sooner than we think, we should at least be familiar with how AM works and what the core principles are behind it.